微機電系統(Microelectromechanical system, MEMS)是一種透過半導體相關的製程步驟,如黃光微影(Photolithography)、薄膜沉積(Thin Film Deposition)、摻雜(Doping)、以及蝕刻(Etching)等,在矽晶圓上製作微小機械結構的技術,也可以進一步和微電子元件整合,建構完整的機電系統,實現微型化的機械結構、感測器(Sensor)、和致動器(Actuator),並應用於生、光、機、電等多元的範疇。

(本文出自國立清華大學動力機械工程系、奈微所:方維倫教授及其團隊,於閎康科技「科技新航道 | 合作專欄」介紹全MEMS 技術的應用發展概況,並詳述研究團隊多年來在兩大 MEMS 前瞻元件「微型揚聲器」及「微掃描面鏡」的技術開發成果,經科技新報修編為上下兩篇,此篇為上篇。)

微機電系統藉由半導體製程所帶來的微縮(Miniaturization)、集成(Integration)、以及批量製造(Batch Fabrication)等優點,使得相關產品具有尺寸小、耗電少、價格低等諸多競爭優勢,也成為許多新興產業,如物聯網、智慧應用(Smart-X)、元宇宙(Metaverse)的關鍵技術,其應用的範圍與需求的數量急遽上升,圖 1 為法國的市場研究公司 Yole 所預測的 MEMS 未來趨勢。由於機械結構的特性,微機電系統不需要跟隨摩爾定律(Moore’s Law)的腳步,致力於縮小元件的尺寸;微機電系統藉由多樣化(diversification)亦即所謂的超越摩爾(More than Moore)的方式,來拓展半導體製程的影響力和應用,因此具有重要的戰略價值,值得國內半導體業者加以重視。

▲ 圖1 MEMS 傳感器的未來趨勢[1]。

▲ 圖1 MEMS 傳感器的未來趨勢[1]。

微機電系統的應用 —— 物聯網至元宇宙

微機電系統的應用概略整理於圖 2,可大致分為:

1.微結構,例如:探針卡(Probe Card)、原子力顯微鏡(AFM)的微型探針,生醫晶片的微流道等[2-4]。

2.微感測器,例如:麥克風、壓力計、加速度計、陀螺儀等[5-7]。

3.微致動器,例如:噴墨頭的加熱器或壓電致動器、德州儀器公司(TI)單槍投影機光投影晶片的面鏡致動器等[8-10]。

▲ 圖2 微機電系統應用領域[43]。

▲ 圖2 微機電系統應用領域[43]。

目前微機電系統的產品仍以感測器為主,早期主要用於提升行車安全,例如胎壓監控的壓力計、安全氣囊啟動的加速度計;隨後也陸續擴展至消費性電子產品,如助聽器的麥克風、體感遊戲機的慣性感測器等,而智慧型穿戴裝置和智慧型手機,更是大量利用微機電感測器尺寸小、耗電低的特色,在有限的空間放置包括麥克風、加速度計、陀螺儀、磁力計、壓力計、溫濕度計、氣體感測器等,提供消費者更多元的人機互動、更優異的操作體驗、和更豐富的資訊。

根據換能器(Transducer)的觀點,微機電系統因為尺寸小,對外來的刺激較為敏感,所以適合應用於感測器;反之因為尺寸小,無法對外界提供足夠的能量輸出,所以在致動器的應用方面,有較多的限制與考量。不過在發展過程中,有兩項相當成功的致動器產品,其中一項是利用微加熱器產生氣泡,然後致動墨水噴出的惠普(HP)噴墨頭,如圖 3 所示[11];另一項是由德州儀器公司(TI)開發的數位光處理(Digital Light Processing, DLP)晶片,利用微機電技術實現數量高達數十萬的微鏡陣列(Micro Mirror Array)如圖 4 [12-13],並利用靜電力致動每一個微鏡單元,來控制像素的色彩和亮度,將影像投影到螢幕。

近年來隨著物聯網、大數據、人工智慧、以及元宇宙等概念興起,帶動微型感測器和致動器的應用範圍與需求,從系統的觀點來審視,微致動器更是不可或缺的元件,在未來不同應用場域將佔舉足輕重的地位。

▲圖3 熱致動之噴墨頭操作原理示意圖[11]。

▲圖3 熱致動之噴墨頭操作原理示意圖[11]。

▲ 圖4 德州儀器公司開發之數位光處理技術所使用的微面鏡陣列[12-13]。

▲ 圖4 德州儀器公司開發之數位光處理技術所使用的微面鏡陣列[12-13]。

微致動器與壓電薄膜

微機電系統是利用半導體製程於晶圓上批量製造與整合,微致動器和傳統的機械致動器,例如內燃機和馬達,無論在外型或驅動原理,皆有著極顯著的差異,目前在文獻上較常見之致動器包括:靜電式(Electrostatic)、電磁式(Electromagnetic)、電熱式(Electrothermal)、以及壓電式(Piezoelectric)等四個類型。前述 HP 噴墨頭屬於電熱式、TI 光投影晶片屬於靜電式致動器。由於電熱式、靜電式致動器與半導體製程有較佳的相容性,因此許多研究皆以此二種方式作為致動元件。

然而各式致動器仍待解決的問題,靜電式致動器必須解決活動空間、靜電吸附(Pull-in)效應、驅動電壓等問題[15]、電磁式致動器往往需要組裝相關的電磁元件,操作過程也有升溫耗能的考量[16]、耗能與可靠度是電熱式致動器的隱憂、壓電式致動器則受限於與半導體製程相容的壓電薄膜取得不易、以及壓電薄膜的穩定性[17-18]。由於壓電材料出色的致動能力及廣泛的應用潛力,許多研究單位和相關企業,皆積極投入壓電薄膜製程技術的開發,也有突破性的發展,使得壓電致動器成為頗受矚目的元件。

壓電材料如氮化鋁(AlN)、鋯鈦酸鉛(Pb(Zr1-xTix)O3, PZT)等等,具備將機械能與電能互相轉換的特性,稱之為壓電效應,而根據其能量轉換的方式,可進一步區分正壓電、逆壓電效應。逆壓電效應是將輸入的電訊號轉換為壓電材料的線性形變(電能轉換為機械能),如圖 5 所示,多膜層堆疊的懸浮微機械結構,將使懸浮微機械結構頂端產生顯著的位移輸出,此設計即壓電致動器。

▲ 圖5 作為壓電致動器之懸浮微機械結構示意圖[43]。

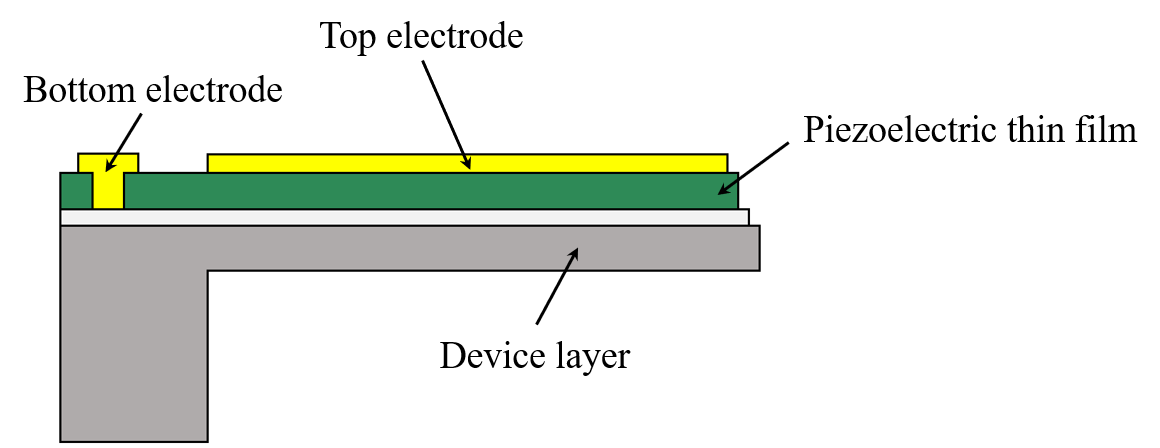

由圖 6 得知,壓電致動器的組成相當簡單,主要包括結構層、電極層、和壓電薄膜,膜層的堆疊及結構、壓電薄膜的形狀設計及材料,都會影響壓電致動器的特性。

▲圖6 壓電致動器之膜層堆疊結構[43]。

▲圖6 壓電致動器之膜層堆疊結構[43]。

一般來說,壓電薄膜的致動能力,通常取決於材料的壓電係數(機電轉換能力),如表 1 所示,在眾多壓電薄膜中,PZT 擁有出色的壓電係數,是備受期待的壓電致動材料。

▲表1 常見壓電材料的壓電係數。

▲表1 常見壓電材料的壓電係數。

近年來由於業界看好壓電薄膜傳感元件的潛力,因此吸引許多儀器供應商和晶圓製造商,投入關鍵設備與材料的開發,預計可以加速壓電薄膜傳感元件商品化的腳步。另一方面,壓電薄膜機械性質的探討,以及其對於相關應用可靠度的影響,都是未來成功商品化必須面對的挑戰。在下篇我們將繼續探討 PZT 壓電薄膜如何發揮其功能,以及廣泛應用在微型揚聲器與微掃描面鏡等前瞻元件中。

(首圖來源:Shutterstock;圖片及資料來源:閎康科技)

延伸閱讀:

參考資料:

[1]http://www.yole.fr/.

[2]Z. Yanwei, Z. Yongxia, and R. B. Marcus, “Thermally actuated microprobes for a new wafer probe card," Journal of Microelectromechanical Systems, vol. 8, no. 1, pp. 43-49, 1999.

[3]J. Brugger, R. A. Buser, and N. F. d. Rooij, “Micromachined atomic force microprobe with integrated capacitive read-out," Journal of Micromechanics and Microengineering, vol. 2, no. 3, pp. 218-220, 1992.

[4]B. He, N. Tait, and F. E. Regnier, “Fabrication of nanocolumns for liquid chromatography,” Anal. Chem., vol. 70, pp. 3790–3797, 1998.

[5]S. C. Lo, C. K. Chan, M. Wu and W. Fang, “Design and Implementation of Differential MEMS Microphones Using the Two Polysilicon Processes for SNR Enhancement,” J. Micromech. Microeng., 30 055006, 2020.

[6]Y. -C. Liu, M. -H. Tsai, S. -S. Li and W. Fang, “A Fully-differential, Multiplex-Sensing Interface Circuit Monolithically Integrated With Tri-axis Pure Oxide Capacitive CMOS-MEMS Accelerometers," TRANSDUCERS & EUROSENSORS XXVII, pp. 610-613, 2013.

[7]N. M. Nguyen, C. Y. Chang, G. Pillai and S. S. Li, “Design of Piezoelectric MEMS Bulk Acoustic Wave Mode-Matched Gyroscopes Based on Support Transducer," MEMS, pp. 338-341, 2021.

[8]P. F. V. Kessel, L. J. Hornbeck, R. E. Meier, and M. R. Douglass, “A MEMS-based projection display," Proceedings of the IEEE, vol. 86, no. 8, pp. 1687-1704, 1998.

[9]M. Wu and W. Fang, “Design and fabrication of MEMS devices using the integration of MUMPs, trench-refilled molding, DRIE and bulk silicon etching processes," Journal of Micromechanics and Microengineering, vol. 15, no. 3, pp. 535-542, 2004.

[10]A. Vergara, T. Tsukamoto, W. Fang, and S. Tanaka, “Integration of buried piezoresistive sensors and PZT thin film for dynamic and static position sensing of MEMS actuator," Journal of Micromechanics and Microengineering, vol. 30, no. 11, p. 115020, 2020.

[11]J. Stasiak, S. Richards, and S. Angelos, “Hewlett Packard‘s inkjet MEMS technology: past, present, and future,” in Proc.SPIE, vol. 7318, p. 73180U, 2009.

[12]https://www.ti.com/dlp-chip/overview.html

[13]D. Michael, “DMD reliability: a MEMS success story,” in Proc. SPIE, vol. 4980, pp. 1-11, 2003.

[14]H. Wang, L. Zhou, X. Zhang, and H. Xie, “Thermal Reliability Study of an Electrothermal MEMS Mirror,” IEEE Transactions on Device and Materials Reliability, vol. 18, no. 3, pp. 422-428, 2018.

[15]M. Wu, H. Lin, and W. Fang, “A Poly-Si-Based Vertical Comb-Drive Two-Axis Gimbaled Scanner for Optical Applications,” IEEE Photonics Technology Letters, vol. 18, no. 20, pp. 2111-2113, 2006.

[16]J. J. Bernstein, W. P. Taylor, J. D. Brazzle, C. J. Corcoran, G. Kirkos, J. E. Odhner, A. Pareek, M. Waelti, and M. Zai, “Electromagnetically actuated mirror arrays for use in 3-D optical switching applications,” J. Microelectromech. Syst., vol. 13, no. 3, pp. 526–535, 2004.

[17]J. Wang, C. Salm, E. Houwman, M. Nguyen, and J. Schmitz, “Humidity and polarity influence on MIM PZT capacitor degradation and breakdown,” IEEE International Integrated Reliability Workshop(IIRW), pp. 65-68, 2016.

[18]M. F. Bevilacqua, V. Casuscelli, S. Costantini, P. Ferrari, and I. Pedaci, “High Temperature Operating Lifetime Test on piezo-MEMS devices," the 6th IEEE International Forum on Research and Technology for Society and Industry(RTSI), pp. 452-456, 2021.

[19]https://www.knowles.com/subdepartment/dpt-ba-receivers/subdpt-hearing-instruments-receivers

[20]https://www.usound.com/products/

[21]https://xmems.com/products/

[22]H. H. Cheng, S. C. Lo, Z. R. Huang, Y. J. Wang, M. Wu, and W. Fang, “On the Design of Piezoelectric MEMS Microspeaker for the Sound Pressure Level Enhancement,” Sensors and Actuators A: Physical, vol. 306, 2020.

[23]Y. J. Wang, S. C. Lo, M. L. Hsieh, S. D. Wang, Y. C. Chen, M. Wu, W. Fang, “Multi-Way In-Phase/Out-of-Phase Driving Cantilever Array for Performance Enhancement of PZT MEMS Microspeaker,” IEEE 34th International Conference on Micro Electro Mechanical Systems(MEMS), pp. 83-84, 2021.

[24]I. Shahosseini, E. Lefeuvre, J. Moulin, E. Martincic, M. Woytasik, and G. Lemarquand, “Optimization and Microfabrication of High Performance Silicon-Based MEMS Microspeaker,” IEEE Sensors Journal, vol. 13, no. 1, pp. 273-284, 2013.

[25]F. Stoppel, C. Eisermann, S. Gu-Stoppel, D. Kaden, T. Giese and B. Wagner, “Novel Membrane-less Two-way MEMS Loudspeaker Based on Piezoelectric Dual-concentric Actuators,” 19th International Conference on Solid-State Sensors, Actuators and Microsystems(TRANSDUCERS), pp. 2047-2050, 2017.

[26]V. A. Aksyuk, F. Pardo, D. Carr, D. Greywall, H. B. Chan, M. E. Simon, A. Gasparyan, H. Shea, V. Lifton, C. Bolle, S. Arney, R. Frahm, M. Paczkowski, M. Haueis, R. Ryf, D. T. Neilson, C. R. Giles, and D. Bishop, “Beam-Steering Micromirrors for Large Optical Cross-Connects," J. Lightwave Technol., vol. 21, no. 3, p. 634, 2003.

[27]https://www.projectorcentral.com/Microvision-SHOWWX_Laser_Pico.htm

[28]https://velodynelidar.com/what-is-lidar/

[29]H. W. Yoo et al., “MEMS-based lidar for autonomous driving," e & i Elektrotechnik und Informationstechnik, vol. 135, no. 6, pp. 408-415, 2018.

[30]https://velodynelidar.com/products/alpha-prime/.

[31]https://www.continental-automotive.com/.

[32]https://quanergy.com/products/s3/.

[33]https://www.fic.com.tw/zh-hant/automotive/ar-hud/

[34]https://www.st.com/content/st_com/en/about/innovation—technology/laser-beam-scanning.html

[35]S. Holmström, U. Baran, and H. Urey, “MEMS Laser Scanners: A Review," Journal of Microelectromechanical Systems, vol. 23, no. 2, pp. 259-275, 2014.

[36]R. Konsta, M. Dmitry, M. E. Y. Oili, and K. Jukka, “Resonating AlN-thin film MEMS mirror with digital control," Journal of Optical Microsystems, vol. 2, no. 1, p. 011006, 2022.

[37]K. Hwang, Y.-H. Seo, J. Ahn, P. Kim, and K.-H. Jeong, “Frequency selection rule for high definition and high frame rate Lissajous scanning," Scientific Reports, vol. 7, no. 1, pp. 14075, 2017.

[38]T. Masanao, A. Masahiro, Y. Yoshiaki, and T. Hiroshi, “A two-axis piezoelectric tilting micromirror with a newly developed PZT-meandering actuator," 2007 IEEE 20th International Conference on Micro Electro Mechanical Systems(MEMS), pp. 699-702, 2007.

[39]U. Baran, D. Brown, S. Holmstrom, D. Balma, W. O. Davis, P. Muralt, and H. Urey, “Resonant PZT MEMS Scanner for High-Resolution Displays," Journal of Microelectromechanical Systems, vol. 21, no. 6, pp. 1303-1310, 2012.

[40]K. Meinel, C. Stoeckel, M. Melzer, S. Zimmermann, R. Forke, K. Hiller, and T. Otto, “Piezoelectric Scanning Micromirror With Built-In Sensors Based on Thin Film Aluminum Nitride," IEEE Sensors Journal, vol. 21, no. 8, pp. 9682-9689, 2021.

[41]G. Mendicino, M. Merli, R. Carminati, N. Boni, A. Opreni, and A. Frangi, “Electro-mechanical validation of a resonant MEMS mirror with PZT actuation and PZR sensing," Proc.SPIE, vol. 11697,2021.

[42]R. P. Dahl-Hansen, F. Tyholdt, J. Gjessing, A. Vogl, P. Wittendorp, J. Vedum, and T. Tybell, “On the Effect of Water-Induced Degradation of Thin-Film Piezoelectric Microelectromechanical Systems," Journal of Microelectromechanical Systems, vol. 30, no. 1, pp. 105-115, 2021.

[43]方維倫教授實驗室